Extraction Process

The journey from raw kratom leaf to potent gold shot begins with extraction, a crucial step in unlocking the alkaloids that give kratom its unique properties.

Harvesting the Leaves

Harvesting the leaves is the first stage of this process. Skilled farmers carefully select mature kratom trees, ensuring the leaves are at their peak potency. These leaves are then meticulously gathered by hand, preserving their quality and maximizing alkaloid content.

Drying and Grinding

Once harvested, the kratom leaves undergo an extraction process to isolate the desired alkaloids. This typically involves using solvents like ethanol or water to dissolve these compounds from the leaf material. The resulting solution contains a concentrated mixture of alkaloids, ready for further refinement.

After extraction, the alkaloid-rich liquid must be carefully dried to remove any residual solvent and prevent degradation of the potent compounds. Various drying techniques are employed, including evaporation, spray drying, or freeze drying, depending on the desired consistency and purity of the final product.

The dried alkaloids are then ground into a fine powder, creating the base for kratom gold shots. This fine powder ensures optimal solubility and absorption when mixed with other ingredients in the final formulation.

Solvent Extraction

Solvent extraction is a common method used to isolate specific compounds from plant material like kratom leaves.

This process involves using a solvent, such as ethanol or water, to dissolve the desired alkaloids from the leaf tissue. The solvent effectively acts as a carrier, pulling the alkaloids out of the plant matrix and creating a solution containing a concentrated mixture of these compounds.

The choice of solvent depends on factors like the solubility of the target alkaloids, potential interactions with other plant constituents, and the intended application of the extract.

Purification and Filtration

Solvent extraction is carefully followed by purification steps to ensure the final product is as pure as possible. Techniques like chromatography or distillation are used to separate unwanted compounds from the desired alkaloids, resulting in a highly concentrated and refined extract.

Filtration plays a vital role in removing any remaining particulate matter from the purified extract. This step ensures clarity and prevents impurities from affecting the final product’s quality and consistency.

Formulation of Gold Shots

The production of kratom gold shots involves a meticulous process that transforms raw leaves into potent, concentrated doses.

Choosing Kratom Strains

Choosing the right kratom strain is crucial for getting the desired effects. Different strains offer varying levels of alkaloids like mitragynine and 7-hydroxymitragynine, which contribute to kratom’s analgesic, stimulating, or relaxing properties.

Red vein kratom strains are often favored for their sedative effects and pain relief potential. Green vein strains tend to provide a balanced experience with both stimulating and relaxing qualities, while white vein strains are known for their energizing and mood-boosting effects.

Factors like individual tolerance, desired effect, and specific medical needs should guide the selection of a kratom strain.

Adding Ingredients

Once the dried alkaloid powder is ready, it’s time to formulate the kratom gold shots. This involves carefully measuring and combining various ingredients to create a potent and flavorful product.

Common ingredients include sweeteners like honey or agave nectar to balance the earthy taste of kratom. Citric acid is often added to enhance flavor and tartness, while natural flavors like fruit juices or extracts can be incorporated for a more appealing taste profile.

Additional ingredients might include electrolytes, vitamins, or minerals to boost nutritional value and support overall well-being.

The precise formulation of kratom gold shots can vary depending on the manufacturer’s desired effects and target market. Some formulations may focus on specific alkaloid ratios for enhanced analgesic or stimulating properties, while others prioritize taste and palatability.

Mixing and Blending

After extraction and drying, the kratom alkaloids are carefully measured and combined with a variety of ingredients to create the gold shot formulation. Sweeteners like honey or agave nectar are added to balance the earthy taste of kratom. Citric acid enhances flavor and tartness, while natural flavors like fruit juices or extracts add an appealing taste profile.

Additional ingredients such as electrolytes, vitamins, or minerals may be included to boost nutritional value and promote overall well-being. The precise ratio of these ingredients varies depending on the manufacturer’s desired effects and target market. Some formulations may emphasize specific alkaloid ratios for enhanced analgesic or stimulating properties, while others prioritize taste and palatability.

These carefully selected ingredients are blended together to create a homogenous mixture, ensuring even distribution of the alkaloids and other components throughout the final product.

Filling and Packaging

The precise formulation of kratom gold shots can vary depending on the manufacturer’s desired effects and target market.

- Some formulations may focus on specific alkaloid ratios for enhanced analgesic or stimulating properties, while others prioritize taste and palatability.

These carefully selected ingredients are blended together to create a homogenous mixture, ensuring even distribution of the alkaloids and other components throughout the final product.

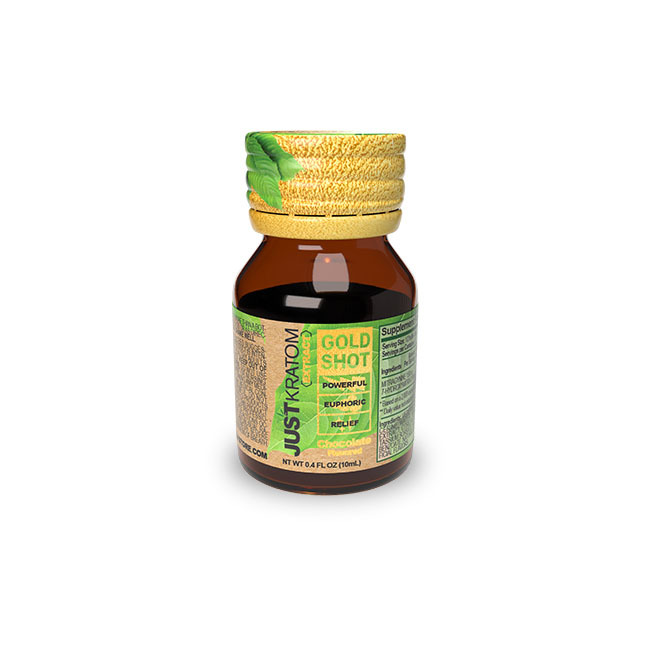

Once the formulation is complete, it’s ready for filling into vials or bottles. This process requires precise measurement and careful handling to prevent contamination or waste.

The filled vials or bottles are then sealed airtight to preserve freshness and potency.

Packaging plays a crucial role in protecting the integrity of kratom gold shots during transport and storage.

- Sturdy containers made from materials like glass or amber plastic help shield the product from light exposure, which can degrade sensitive alkaloids.

- Protective coatings or labels may be used to further prevent contamination or tampering.

- Accurate labeling is essential for providing consumers with clear information about the product’s contents, dosage recommendations, and potential side effects.

Quality Control Measures

Quality control measures are paramount in ensuring the safety, efficacy, and consistency of kratom gold shots. From the initial stages of harvesting and extraction to the final packaging, stringent protocols are implemented at every step of the production process.

Testing for Purity and Potency

Quality control measures play a vital role in guaranteeing the safety, potency, and consistency of kratom gold shots. These measures encompass rigorous testing throughout the production process to ensure the product meets established standards.

Testing for purity is crucial to identify and eliminate any contaminants that may be present in the raw materials or during processing. Techniques like chromatography and mass spectrometry are employed to analyze the composition of the final product, verifying the absence of harmful substances like pesticides, heavy metals, or microbial contamination.

Potency testing ensures that each batch of kratom gold shots contains the desired concentration of alkaloids. Methods such as high-performance liquid chromatography (HPLC) allow for precise measurement of alkaloid levels, ensuring consistent dosage and therapeutic effects.

Strict adherence to good manufacturing practices (GMP) is essential throughout the production process. This involves maintaining a clean and controlled environment, implementing standardized procedures for handling materials and equipment, and conducting regular audits to identify and address any potential issues.

Ensuring Safety Standards

Quality control measures are paramount in ensuring the safety, efficacy, and consistency of kratom gold shots. From the initial stages of harvesting and extraction to the final packaging, stringent protocols are implemented at every step of the production process.

- Purity testing is crucial to identify and eliminate any contaminants that may be present in the raw materials or during processing. Techniques like chromatography and mass spectrometry are employed to analyze the composition of the final product, verifying the absence of harmful substances like pesticides, heavy metals, or microbial contamination.

- Potency testing ensures that each batch of kratom gold shots contains the desired concentration of alkaloids. Methods such as high-performance liquid chromatography (HPLC) allow for precise measurement of alkaloid levels, ensuring consistent dosage and therapeutic effects.

- Strict adherence to good manufacturing practices (GMP) is essential throughout the production process. This involves maintaining a clean and controlled environment, implementing standardized procedures for handling materials and equipment, and conducting regular audits to identify and address any potential issues.

Order Kratom Gold Shots for Your Health Goals

- Why CBD Gummies Are A Popular Alternative To Prescription Medications - November 14, 2025

- What Is The Best Filler For The Temple Area - November 12, 2025

- What Are The Benefits Of CBD Gummy Edibles For Sleep - November 11, 2025